Categories

New products

-

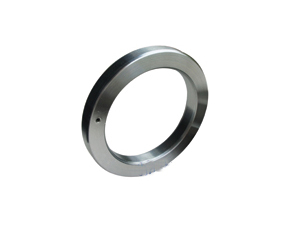

RX Ring Joint Gasket

Get verified list of RX Ring Joint Gasket, RX Ring Joint Gasket manufacturers, suppliers and exporters. These RX Ring Joint Gasket manufacturing companies provide high quality products as per your requirement.

-

BX Ring Joint Gasket

Get verified list of BX Ring Joint Gasket, BX Ring Joint Gasket manufacturers, suppliers and exporters. These BX Ring Joint Gasket manufacturing companies provide high quality products as per your requirement.

-

Lens Ring Joint Gasket

Get verified list of Lens Ring Joint Gasket, Lens Ring Joint Gasket manufacturers, suppliers and exporters. These Lens Ring Joint Gasket manufacturing companies provide high quality products as per your requirement.

-

Double Jacket Gasket

Get verified list of Double Jacket Gasket, Double Jacket Gasket manufacturers, suppliers and exporters. These Double Jacket Gasket manufacturing companies provide high quality products as per your requirement.

-

Corrugated Gaskets

Get verified list of Corrugated Gaskets, Corrugated Gaskets manufacturers, suppliers and exporters. These Corrugated Gaskets manufacturing companies provide high quality products as per your requirement.

White PTFE Packing with Aramid Corners

This packing is a multi-yarns packing. The corners of packing are made of aramid fiber yarns impregnated with PTFE, the friction faces are made of PTFE yarns. This structure enhances the lubrication ability of aramid fiber and improves the strength of the pure PTFE.

Description:

PTFE Packing with aramid fiber corners is a multi-yarn packing, the corners of packing are made of aramid fiber yarns. Impregnated with PTFE, the friction faces are made of pure PTFE yarns. It can be lubricated with silicones oil.

Kaxite P308W White PTFE and Aramid in Zebra Braided Packing

Typical Application

> This is a universal packing which can be used for pumps in all types of industry.

> Chemical, petrochemical, pharmaceutical, food and sugar industries, pulp and paper mills, etc.

Prime Features

> Enhances the lubrication ability of aramid fiber and improves the strength of PTFE

> The packing will no stain in pulp and paper mill, pharmaceutical, food and sugar industries.

Technical Data

| Material | Aramid fiber and PTFE | |

| Temperature Range | -100 up to +280 oC | |

| Process | Rotating | 20 bar |

| Reciprocating | 100 bar | |

| Static | 180 bar | |

| Shaft Speed | 12m/s | |

| PH | 2~12 | |

| Density | Appr. 1.4g/cm3 | |